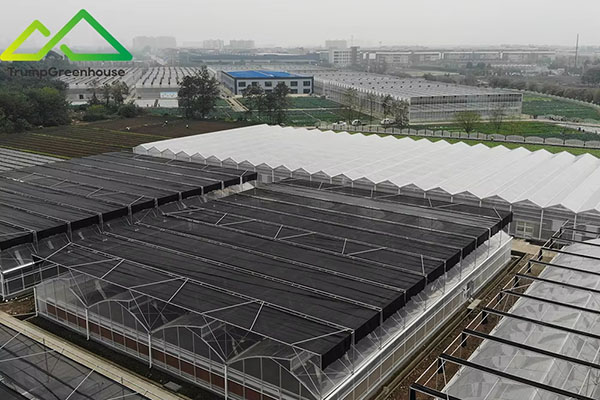

Innovating Greenhouse BiPV Solutions From Panda Greenhouse

Products Description

Panda Greenhouses' PV Greenhouse Solutions effectively address key challenges in greenhouse agriculture through the following aspects:

1. Construction Costs

Traditional PV greenhouses require additional mounting structures to support external solar panels. Panda Greenhouses' patented PV modules directly replace conventional cladding materials, eliminating redundant structures and reducing material specifications – significantly lowering construction costs.

2. Operational Costs

Labor, materials (seeds, fertilizers, etc.), machinery, and energy constitute the major operational expenses. Panda Greenhouses' integrated PV system fully meets the facility's electricity demand, with surplus power available for sale – slashing energy costs and generating additional revenue.

| Photovoltaic Greenhouse Types | Venlo,Large Gable Roof, Customized |

| Photovoltaic Greenhouse Span | 8m-12m, Customized |

| Photovoltaic Module Light Transmittance | 0%/10%/40%(Customized Light Transmittance) |

| Small PV Greenhouse (500-1,000m2) | Approximately 20,000-50,000 kWh |

| Medium PV Greenhouse (1,000-5,000m2) | Approximately50,000-250.000 kWh |

| Large PV Greenhouse (5,000m2+) | Can exceed 250,000kWh |

0% Light Transmittance :Edible Fungus Cultivation ,Plant Factories (Artificial Lighting Type),Scientific Research & Experiments, Aquaculture/Livestock Farming, Education & Exhibition, Industrial Applications,

10% Light Transmittance :Shade-Tolerant Crop Cultivation ,Edible Fungi & Specialty Crops

Plant Factories (Hybrid Lighting Type),Ecotourism & Exhibition, Aquaculture, Specialized Industrial Uses, Education & Science Outreach,

40% Light Transmittance :Vegetable Production, Floriculture, Fruit Tree Seedling Cultivation

Medicinal Herb Cultivation, Seedling Propagation & Cutting, Ecotourism & Exhibition, Scientific Research, Mixed-Crop Cultivation, Agrivoltaics (PV Greenhouses),Education & Science Outreach

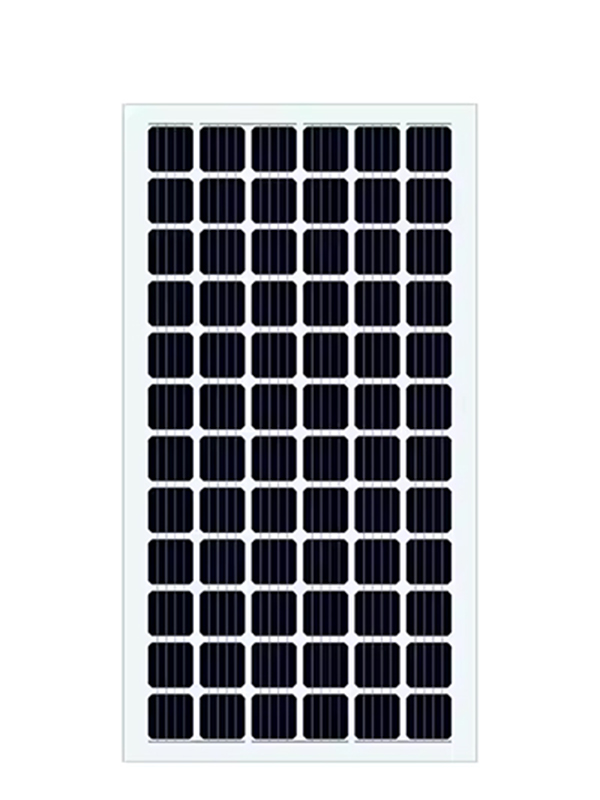

0% Light Transmittance

Power Range: 435W-460W

Cell Type: Monocrystalline Silicon

Dlmenslons(LxWxT): 1761*1133*4.75mm

Welght:11.75kg

Annual Degradatlon Rate: -0.40%

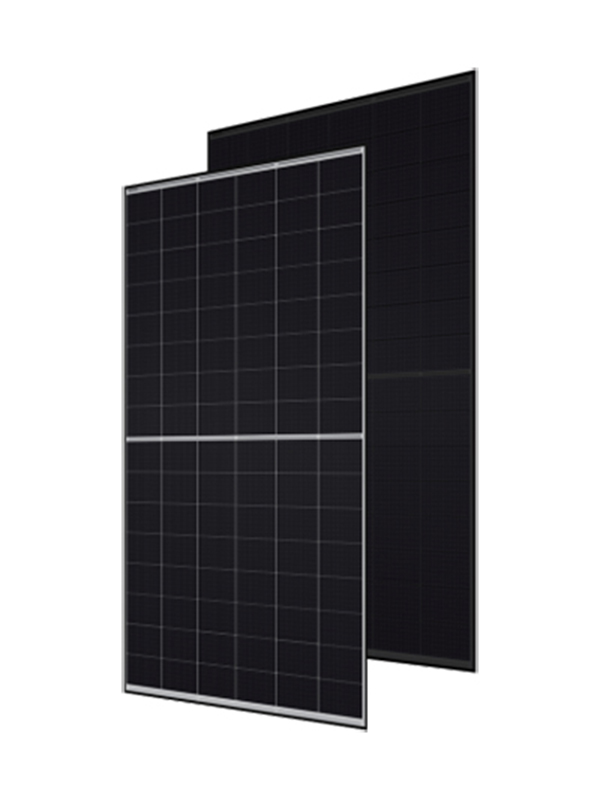

10% Light Transmittance

Power Range: 410W-440W

Cell Type: Monocrystalline Silicon

Dlmenslons(LxWxT): 1750*1128*7.4mm

Welght:32.5kg

Annual Degradatlon Rate: -0.50%

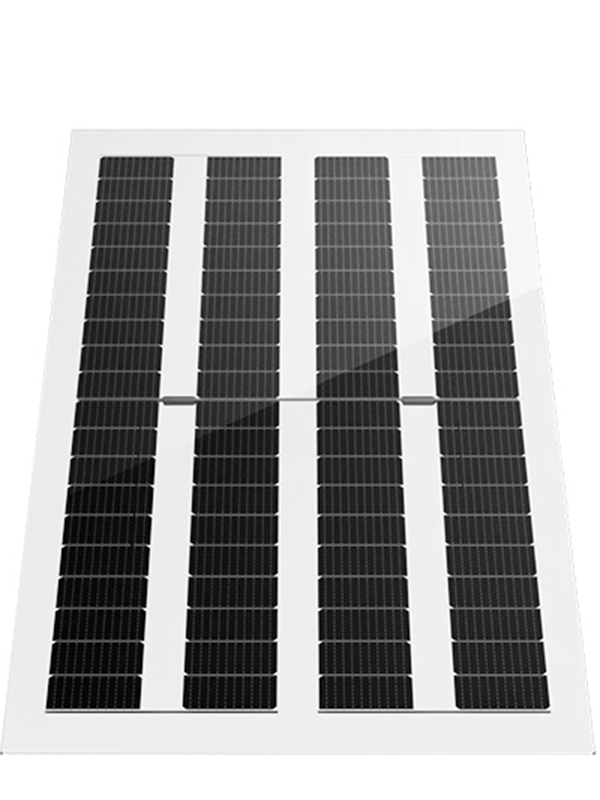

40% Light Transmittance

Power Range: 290W-310W

Cell Type: Monocrystalline Silicon

Dlmenslons(LxWxT): 1750*1128*7.4mm

Welght:32.5kg

Annual Degradatlon Rate: -0.50%

Greenhouse System

Cooling system

For most greenhouses, the extensive cooling system we use are fans and cooling pad. When the air penetrates the cooling pad medium, it exchanges heat with the water vapor on the surface of the cooling pad to achieve humidification and cooling of the air.

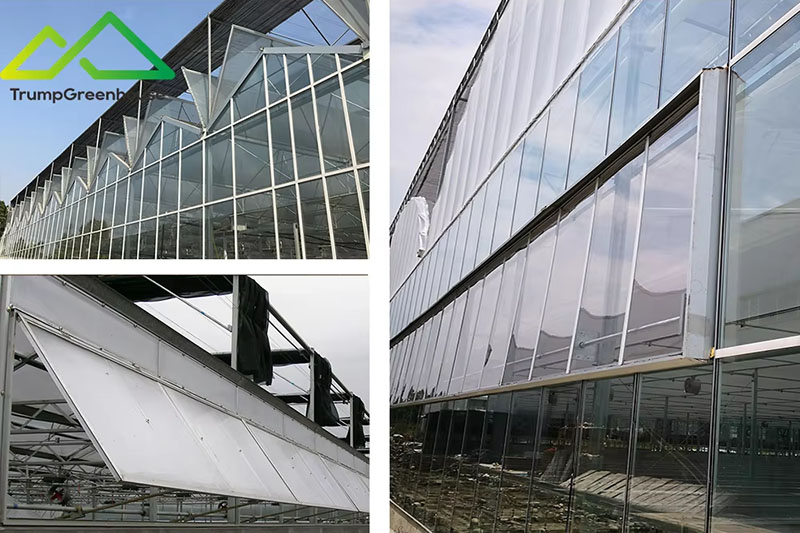

Shading system

For most greenhouses, the extensive cooling system we use are fans and cooling pad. When the air penetrates the cooling pad medium, it exchanges heat with the water vapor on the surface of the cooling pad to achieve humidification and cooling of the air.

Irrigation system

According to the natural environment and climate of the greenhouse. Combined with the crops that need to be planted in the greenhouse. We can choose a variety of irrigation methods; droplets, spray irrigation, micro -mist and other methods. It is completed at one time in hydrating and fertilization of plants.

Ventilation system

Ventilation is divided into electric and manual. Different from the ventilation position can be divided into side ventilation and top ventilation.

It can achieve the purpose of exchanging indoor and outdoor air and the purpose of reducing the temperature inside the greenhouse.

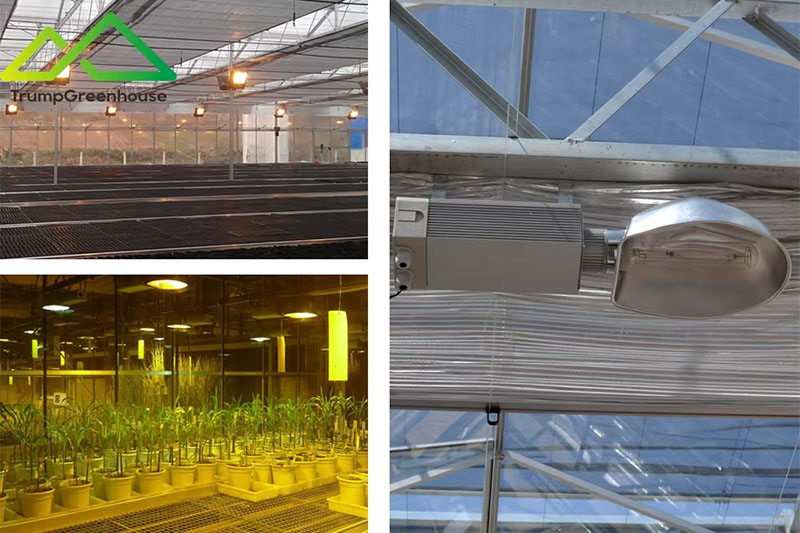

lighting system

Setting the optical system in the greenhouse has the following advantages. First, you can provide a specific spectrum for plants to make plants grow better. Secondly, the light required for plant growth in the season without light. Third, it can increase the temperature inside the greenhouse within a specific range.